CNC Machining & Plastic Injection Molding

The Future of CNC Machining & Plastic Injection Molding: Where Precision Meets Innovation

In the world of modern manufacturing, two technologies stand tall:

CNC machining and plastic injection molding.

They are the backbone of how the physical world around us is made—from the smartphone cases in our pockets to the engine parts in vehicles. While these methods may seem traditional, both are undergoing a silent revolution fueled by automation, AI, and digital integration.

This isn’t just a story of machines—it’s a story of how precision, speed, and creativity are coming together to shape the future of manufacturing.

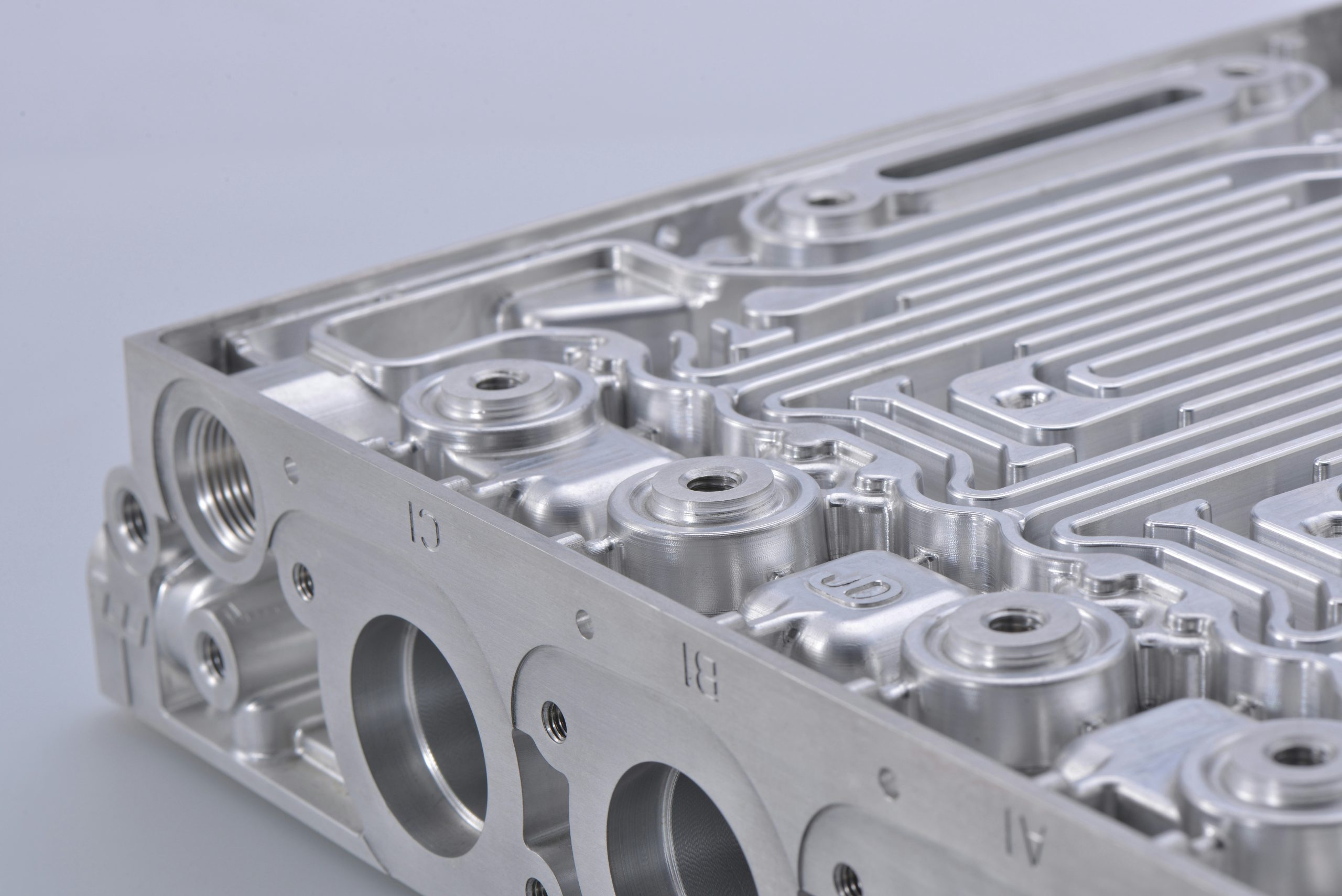

CNC Machining: Precision Meets Intelligence

CNC (Computer Numerical Control) machining has long been the go-to method for producing high-accuracy metal and plastic parts. But today’s CNC is not just about cutting with speed—it’s about cutting smart.

What’s Changing:

- AI-enhanced CAM software can now optimize tool paths automatically, reducing machining time and tool wear.

- Real-time monitoring systems detect vibration, tool damage, or overheating—then automatically adjust parameters.

- Hybrid CNC machines are combining milling, turning, and even 3D printing in one setup.

The Future Looks Like:

- Autonomous CNC cells with robotic part handling

- Cloud-based CNC simulations that predict issues before production

- Integration with digital twins for zero-defect manufacturing

Bottom line? CNC machining is becoming faster, smarter, and more accessible—even for small-scale makers.

Plastic Injection Molding: Mass Production Reinvented

Plastic injection molding remains the gold standard for mass-producing plastic parts—especially when you need consistency, speed, and scalability. But like CNC, it’s also evolving in big ways.

What’s Changing:

- AI-driven mold flow analysis can now detect issues like air traps, sink marks, and warping before a mold is even made.

- Smart injection machines automatically adjust pressure, speed, and temperature in real-time based on material behavior.

- Sustainable materials (bioplastics, recycled polymers) are becoming more common—and molds must now accommodate these variations.

The Future Looks Like:

- Digital molds that are validated with simulations before ever being built

- Micro-injection molding for miniature, precise parts (especially for medical & electronics)

- Fully automated production cells, including robotic part removal and QC scanning

CNC + Injection Molding + AI = Smart Manufacturing

Here’s where it gets exciting:

We’re no longer thinking in separate production methods—we’re building fully integrated manufacturing ecosystems.

- CNC is used to create precision molds for injection molding.

- Injection-molded prototypes are tested, improved, then adjusted using digital feedback loops.

- AI connects the dots—optimizing designs, predicting defects, and suggesting geometry tweaks for better performance.

This feedback loop is shortening product development from weeks to days.

What Designers and Engineers Should Focus On

If you’re a product designer, 3D modeler, or mechanical engineer—here’s how to stay future-ready:

✅ 1. Design for Manufacturing (DFM)

Understand both CNC and injection molding limitations:

- Add draft angles, proper wall thickness, and radii in plastic part designs.

- Avoid over-complicated geometries in CNC parts unless truly necessary.

✅ 2. Embrace Simulation Tools

Use mold flow simulations, toolpath visualizers, and tolerance stack-up analysis tools to design smarter from the start.

✅ 3. Think in Terms of Efficiency

Manufacturing is about scale and repeatability.

- Choose materials wisely (recyclables, cost-effective plastics)

- Design parts that require less machining, fewer mold revisions, and minimal post-processing

✅ 4. Collaborate with Machines

CNC and molding machines are no longer dumb tools—they’re becoming collaborative partners. The more you understand their language (G-code, tool libraries, pressure curves), the more powerful your designs become.

Final Thoughts: A New Era of Making

CNC machining and plastic injection molding are no longer just about removing or shaping material. They’re part of a smart, AI-augmented manufacturing future where digital and physical work hand-in-hand.

Whether you’re creating a one-off prototype or producing a million units—efficiency, quality, and intelligence will define the next era of manufacturing.

So, the question isn’t:

“Will CNC and injection molding still be relevant in the future?”

It’s:

“How ready are you to design for the future they’re building?”